|

Dinghua Technology |

| Home | Product | News | Service | About us | Contact us |

mobile screen fixed by side screw

DH-CP2 Specification and technical parameters:

Products specifications:

1.Power: 600W

2.Voltage: 220V and 110V are available

3.Size: 550*350*280mm

4.NW: 19KG

5.GW: 22KG

6.Packing: carton size: 530*350*270mm

Products features:

1.Auto heating metal plate,maximum temperature is 400 centigrade

2.Safety power system inside, avoiding the electric leakage problem

3.Anti static body material,prevent the LCD and the flex cable being damaged from the static

4.Easy installation

5.Smooth metal plate to hold the touch screen without any damaged

6.Power supply AC 85V to AC 265V 50Hz ,almost for users from all over the world

7.Temperature should be set to 80 centigrade to 100 centigrade,when you do the job on iphone and galaxy series etc.

8.Compatible for LCD or LED screen assembly

9.Safety power system to avoid leakage

10.200cm last long the life of the wire you use to separate, and prevent your hands be hurt by the high temperature platform

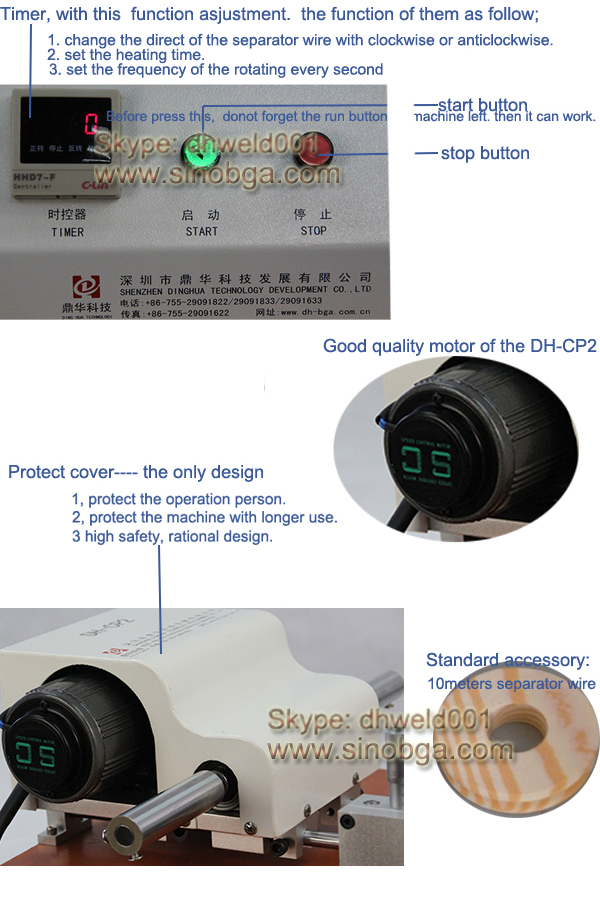

Operating Instruction:

1.Turn the power switch on.

2.Turn the temperature controller on, and set the temperature between 60 and 80 degree.

3.Wind wire on the rollers.

4.Fix the wire on the roller of the left side motor. Wind the wire from top to bottom, then adjust the steering button to up position. Go on winding wire bypass the front two rollers. Then turn on the rotary switch. Wind the wire about 3-5m, turn off the rotary switch.

5.Pull the wire tight, and wind the wire from bottom to top, then fix the other end on the roller of the right side motor. Adjust the steering button down. After the wire rotary half on the wheel, turn off the rotary switch. Finally, adjust the steering button to horizontal position.

6.Adjust the motor from the top of the skidway about 2 cm.

7.Put the LCD on the operating floor.

8.Adjustment the wire and heating stage on the horizon, then turn the automatic mode on. Adjust the proper speed, keep the wire and screen certain radian. Slowly push heating stage by hand.

9.When reach the end of the LCD assembly, quickly push the heating stage back and forth 2 times. After finishing the separation, just separated the lcd and touch panel by hand.

10.Adjust the rotary switch to the low position, and trun off other buttons, finally trun off the power switch.

11.Note: Adjust the steering button up, the machine will run clockwise; Adjust the steering button down, the machine will run anticlockwise; horizontal position will not run.

Note:

1. Do not produce the heat more than 110 degree when operating; otherwise the high temperature may destroy the phone accessories

2. As different country has different current or voltage standard, we have Voltage 220V and 110V for your choice; please choose the right one which meets your country's voltage standard

Why us?

Humanized design:

Safety/Caution instructions:

About Us |

News&Events |

Products |

Service |

Contact Us |

|