DH-A09L BGA rework station

DH-A09L BGA rework station

Category:HR BGA rework station

DH-A09L:

Special feature:

- Imported heater, high quality, durable.

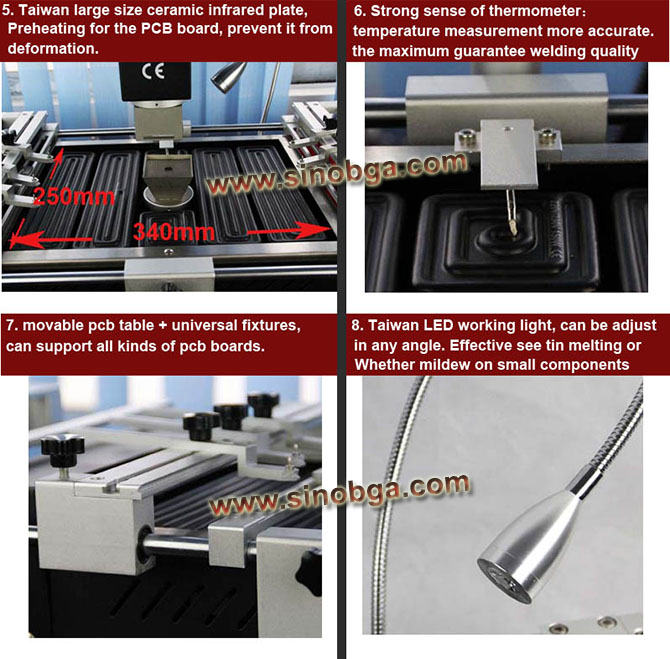

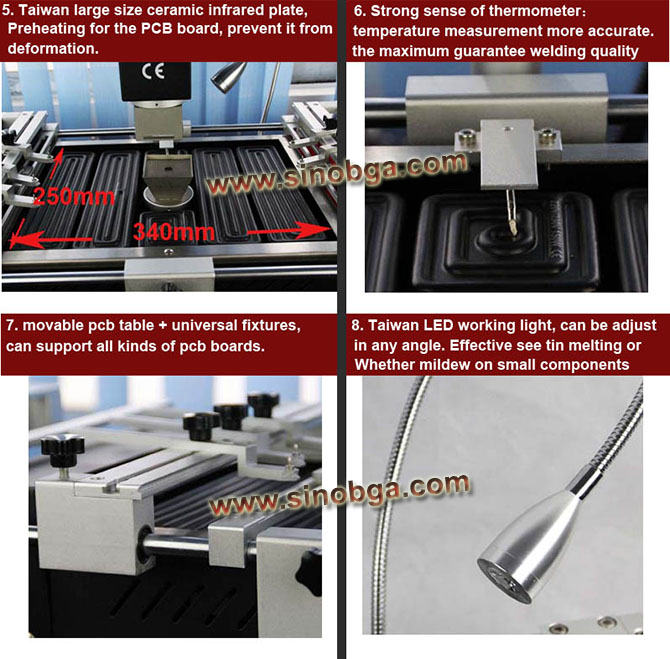

- Taiwan infrared pre-heating ceramic plate,

- Adopt three heating zone, upper heater and lower heater are hot air, bottom is Infrared preheat zone.

- K type close loop control, the temperature accuracy will be on ±2°C

- Equiped with various different size nozzles, customized available.

- High power cross flow cooling fan, prevent the PCB from deformation.

- Sound hint system: there is voice reminder 5s-10s before the completion of heating,to get the operator prepared

- security measure: overheat guard and emergency stop function

Humanized design:

- Upper heater can move up/down, front/back, rotate freely

- Strong sense of thermometer, temperature measurement more accurate

- With a temperature sensor, analyse the temperature and testing the actual temperature.

- PCB clamp (V-groove) with universal fixture, suitable for all kinds of BGA.

- It can set 8 segments heating, and store 10 groups temperature profile

- Taiwan led working light.

- Colorful buttons in English and Chinese, easy recognize and use

- CE certification, with emergency switch and automatic power-off protection device when emergency happens

Application:

Suitable for all kinds of BGA repairing (CCGA、BGA、QFN、 CSP、LGA、Micro SMD、MLF...)

Lead and Lead-free

|

Total Power

|

4800W

|

|

Top heater

|

800W

|

|

Bottom heater

|

Second heater 1200W, IR preheating 2700w

|

|

Power

|

AC220V±10% 50/60Hz

|

|

Dimensions

|

L520×W490×H700 mm

|

|

Infrared heat size

|

L250×W340 mm

|

|

Positioning

|

V-groove, PCB support can be adjusted in any

direction with external universal fixture

|

|

Temperature control

|

K Sensor, Closed loop

|

|

Temp accuracy

|

±2℃

|

|

PCB size

|

Max 400mmⅹ390mm Min20mmⅹ20mm

|

|

BGA chip

|

5*5~55*55mm

|

|

Minimum chip spacing

|

0.15mm

|

|

External Temperature Sensor

|

1(optinal)

|

|

Net weight

|

27KG

|