|

Dinghua Technology |

| Home | Product | News | Service | About us | Contact us |

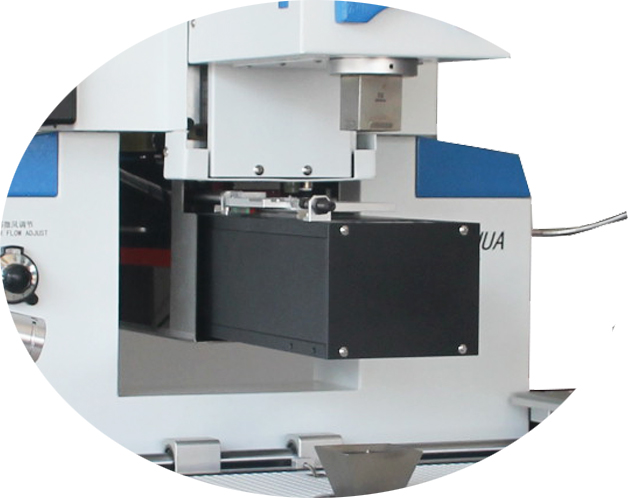

DH-A4 BGA rework system is a state-of-the-art device that has a lot of positive features. This system is designed to offer high-quality BGA rework and reflow to ensure a top-notch performance for different electronic devices. Its advanced technology and user-friendly design make it easy to use, and it delivers reliable and efficient results consistently.

The DH-A4 BGA rework system is equipped with precision control tools that provide the best temperature and pressure settings for different BGA components. This ensures that the device is not damaged during rework or reflow, and the final output matches the original specifications. Additionally, the system is compact and sleek, ensuring that it is easy to work with in confined spaces.

The system also comes with a highly intuitive and user-friendly interface. This makes it simple for technicians to operate, maintain, and troubleshoot the machine when necessary. The easy-to-use menu options also ensure that adjustments can be made quickly and easily to ensure that the BGA device being worked on is reworked to the highest standards.

One other key advantage of the DH-A4 BGA rework system is its versatility. It is designed to work on a wide range of different electronic components and devices, making it ideal for use in almost any electronic repair facility. Whether you need to rework small components or larger ones, the DH-A4 BGA rework system is the perfect choice for all your needs.

In summary, the DH-A4 BGA rework system is an outstanding and highly advanced device that offers a wide range of benefits. Its precision, efficiency, and user-friendly design make it an ideal choice for electronic repair facilities of all sizes. If you are looking for the best BGA rework system, then the DH-A4 BGA rework system is the perfect choice for you.

Monitor/display screen

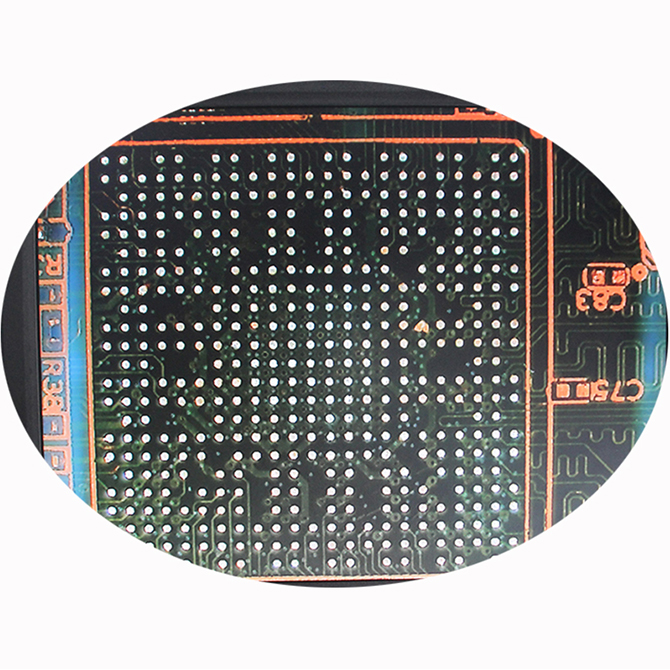

15 inches, 1080 P (HD) , zoom in or out 10~220 x, no matter how small the dots are , they will be observed clearly.

Functional buttons for hot air and optical CCD alignment system

Top air flow adjusting used for upper hot air adjusted, when micro chip soldering, the hot air can be reduced by

rotating the knob, it has 10 classes, usually, when the IC , BGA , QFN and other chips is less than 8*8 mm, don't

use 5-class or higher 5-class, when soldering chip with 20*20 mm or bigger, the 6-class or higher can be used.

Optical alignment system

Full automatic optical CCD and chip feeder, optical CCD imported from Japan, which can split two colors and imaging on monitor screen, chip feeder can be for chip with 1*1~80*80 mm placed on or picked up from. when machine starts to

work, both optical CCD and chip feeder will be automatically running for vacuum sucker (designed in top head) picking

up for aligning, when alignment is OK, they will be back to original position.

About Us |

News&Events |

Products |

Service |

Contact Us |

|