|

Dinghua Technology |

| Home | Product | News | Service | About us | Contact us |

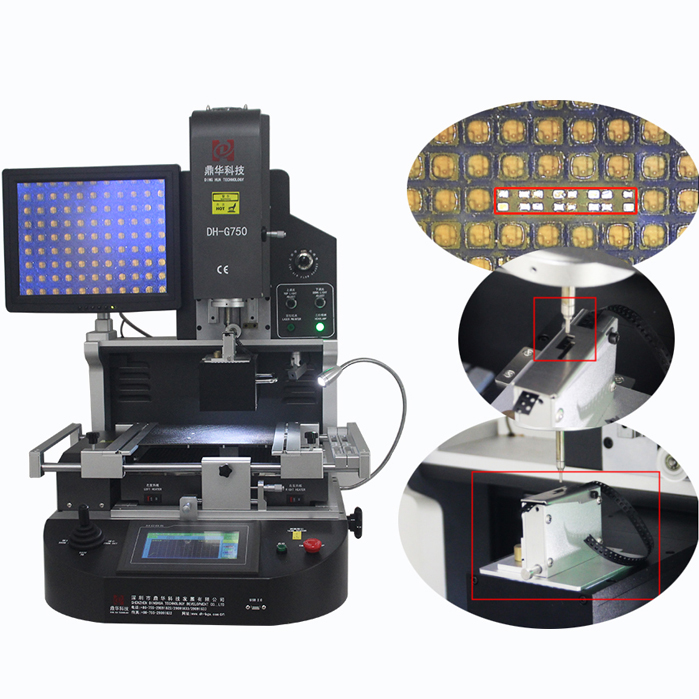

DH-G750 Automatic LED BGA VGA rework station for TV, light and other panel

DH-G750 LED rework machine

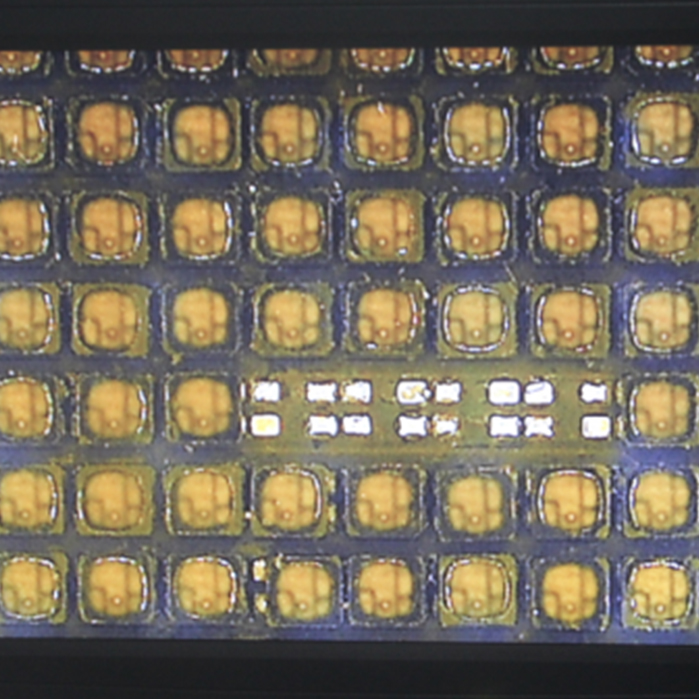

Optical CCD lens for LED chip imaging on the monitor screen

LED chip size low to 0.5*0.5mm, also the machine can be used for other chips, such as, BGA VGA and POP etc, up to 80*80mm.

LED chips leaving with

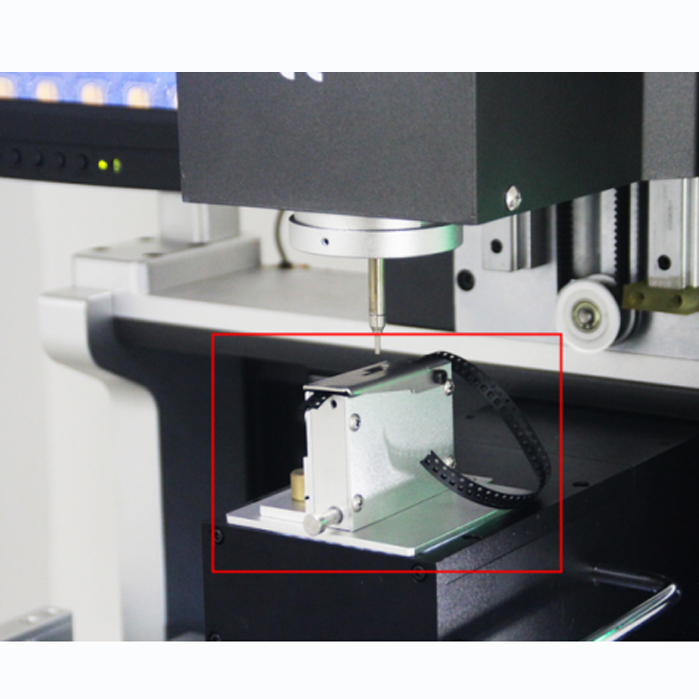

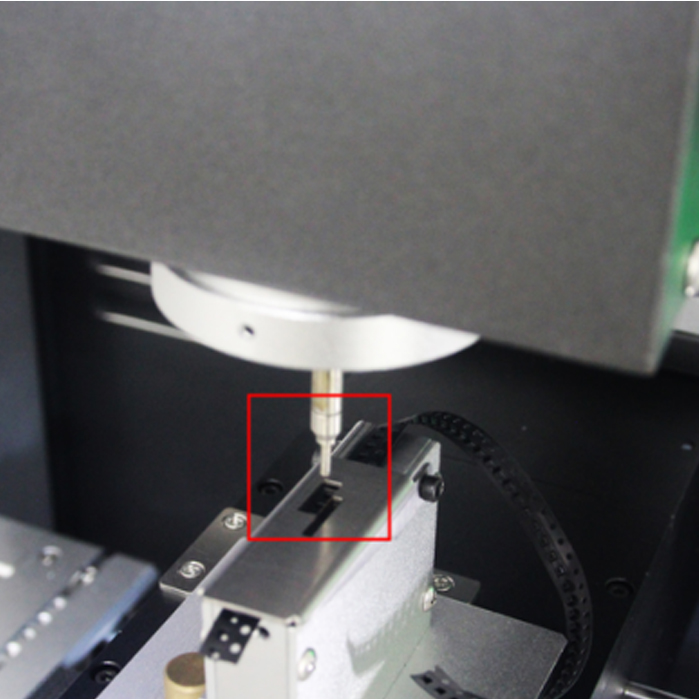

A reel of LED lamp beads can be put on fixture one time, to save time for take chips again from far position, also convenient to solder the chip on .

1. Function and feature:

a.Optical alignment system. LED beads mounting precisely, which make no shifting/misplacement come true.

b.Air-flow adjusted function, the air-flow can be adjusted as per chip’size,more effective reworking,even though tiny chip will not be blown away.

c.Laser positioning,make a PCBa fixed at one time.

d.With LED beads uploading fixture,a reel of LED beads being put one time,which can avoid the process for LED beads picked up, so that the reworking efficiency improves for times;

e.One piece of steel mesh mat above the IR preheating area,which works for LED beads or other small components not dropping inside of machine ;

f.The port of outer testing temperature for temperature tested at all the time, temperature controlling is precise and reliable.

g.Touchscreen operation,programs installed beforehand;

h.Two operations: Manual and automation,adjusting or massive reworking is more simple and easier;

i.USB port available,for software upgraded and multiple dates exported.

2. Product description

a. High-definition touch screen man-machine interface, integrated motion control card control, and instantaneous curve analysis function. Real-time display setting and measured temperature curve, and analysis and correction of the curve.

b. High-precision K-type thermocouple closed-loop control and automatic temperature compensation system, the precise control of the integrated motion control card keeps the temperature deviation at ±1 degree. At the same time, the external temperature measurement interface realizes the precise detection of temperature and realizes the actual measurement. Accurate analysis and proofreading of temperature profiles.

c. Adopt stepping motion control system: stable, reliable, safe and efficient; adopt high-precision digital video alignment system, PCB board positioning adopts V-shaped groove, adopts linear sliding seat, makes X, Y and Z three axes Can be fine-tuned or fast-positioned, convenient, accurate, to meet the different PCB layout methods and the positioning of PCB boards of different sizes.

d. Flexible and convenient removable universal fixture protects the PCB, prevents PCB edge device damage and PCB deformation, and can adapt to various BGA package size rework.

f. For LED lamp bead repair, LED lamp bead feeding device is available, and the minimum "1*1" LED lamp bead can be repaired.

g. Equipped with a variety of alloy air nozzles, which can be rotated and positioned 360 degrees, easy to install and replace;

h. Three temperature zones are independently heated up and down, and three temperature zones can simultaneously control multiple sets of multi-stage temperature to ensure the optimal welding effect is achieved simultaneously in different temperature zones. Heating temperature, time, slope, cooling, and vacuum can all be set on the HMI.

i. sections of temperature control can be set in the upper and lower temperature zones, which can store the temperature curve massively. It can be called according to different BGAs at any time. Curve analysis, setting and correction can also be performed on the touch screen. The three heating zones use independent PID algorithm to control heating. Process, temperature is more uniform, temperature is more accurate;

j. Use high-power cross-flow fan to quickly cool the PCB board to prevent deformation of the PCB board, and achieve intelligent automatic control during the process of placement, welding and disassembly;

k. The joystick can be used to control the head to move up and down and zoom in and out. The operation is quick and convenient.

l. Configure the voice control “early alarm” function. In the voice control mode, the operator will be prepared 5 to 10 seconds before the disassembly and welding are completed. After the upper and lower hot air stops heating, the cooling system starts, and the cooling is automatically stopped after the temperature drops to normal temperature. Ensure that the machine does not age after the heat has warmed up!

m. CE-certified, with emergency stop switch and automatic power-off protection device for sudden accidents.

About Us |

News&Events |

Products |

Service |

Contact Us |

|